Why Choose US?

Contact US

What is Torsion Spring?

A torsion spring is an elastic component that stores mechanical energy by twisting around its axis, generating restoring torque proportional to the rotation angle. Main types include helical torsion springs, clock springs, and torsion bars.-

Axial Lead Air-Core Inductor C···

Axial Lead Air-Core Inductor Coil

-

Axial Lead Air-Core Inductor C···

Axial Lead Air-Core Inductor Coil

Read more

-

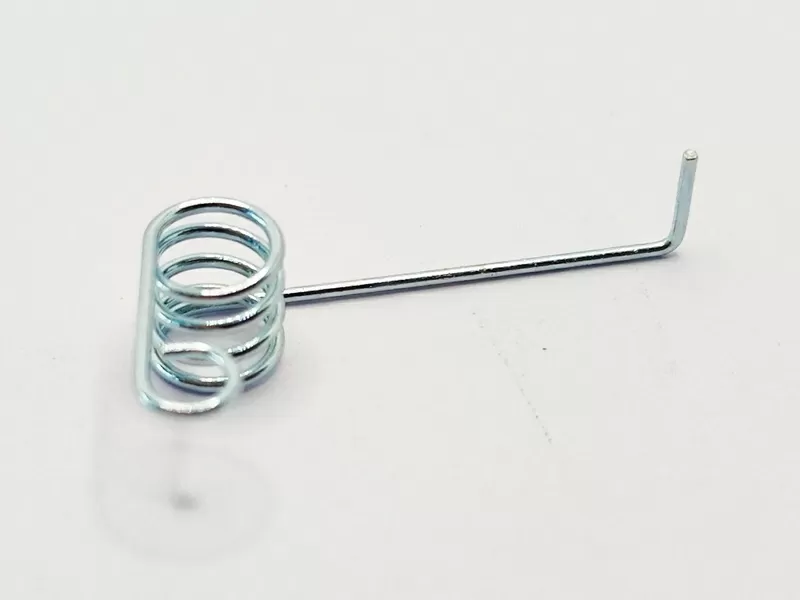

Single torsion spring with gap

Single torsion spring with gap

-

Single torsion spring with gap

Single torsion spring with gap

Read more

-

Marked Wire Coil Spring Compon···

Marked Wire Coil Spring Components (GQ Ring ···

-

Marked Wire Coil Spring Compon···

Marked Wire Coil Spring Components (GQ Ring and Black "5" Spring)

Read more

-

Single torsion spring without ···

Single torsion spring without gap

-

Single torsion spring without ···

Single torsion spring without gap

Read more

-

Micro Metal Coil Elastic Assem···

Micro Metal Coil Elastic Assembly and Compre···

-

Micro Metal Coil Elastic Assem···

Micro Metal Coil Elastic Assembly and Compression Spring

Read more

-

Spring steel wire,single torsi···

Spring steel wire,single torsion

-

Spring steel wire,single torsi···

Spring steel wire,single torsion

Read more

-

Precision Metal Coil Spring an···

Precision Metal Coil Spring and Rod-End Ring···

-

Precision Metal Coil Spring an···

Precision Metal Coil Spring and Rod-End Ring Component

Read more

-

Precision Metal Wire Elastic C···

Precision Metal Wire Elastic Components (HD ···

-

Precision Metal Wire Elastic C···

Precision Metal Wire Elastic Components (HD Coil Rod and LG Torsion Spring)

Read more

-

Micro Rectangular Wire Spring ···

Micro Rectangular Wire Spring Frame

-

Micro Rectangular Wire Spring ···

Micro Rectangular Wire Spring Frame

Read more

-

double torsion spring,center a···

double torsion spring,center arms

-

double torsion spring,center a···

double torsion spring,center arms

Read more

-

Industrial Extension Coil Spri···

Industrial Extension Coil Spring

-

Industrial Extension Coil Spri···

Industrial Extension Coil Spring

Read more

-

single torsion spring,asymmetr···

single torsion spring,asymmetrical arms

-

single torsion spring,asymmetr···

single torsion spring,asymmetrical arms

Read more