Innovations in Spring Technology

From traditional elastic components to high-tech products integrating materials science, intelligent control and interdisciplinary applications

Material Innovation: From Alloy Revolution to Nanostructures

1. Shape Memory Alloys (SMA)

-

Shape memory alloys represented by nickel-titanium alloys (Ni-Ti) give springs "memory" functions through reversible martensite-austenite phase transitions.

-

One-way memory springs recover their original shape when heated after being deformed at low temperatures, while two-way memory springs can switch between two shapes at high and low temperatures, integrating sensing, actuation and transmission.

-

Such springs can automatically deploy at body temperature in medical devices (such as vascular stents), withstand extreme environments from -100°C to 300°C in aerospace satellite deployment mechanisms, with a lifespan exceeding one million cycles.

2. Nano Springs and Composite Materials

Nano Springs

Using chemical vapor deposition (CVD) or electrospinning technology, spiral structures with diameters of only nanometers are manufactured. Their unique DNA-like double helix morphology can be integrated into flexible circuits, giving folding screen hinges self-healing capabilities.

Composite Reinforcement Materials

Carbon nanotube composite nickel-titanium alloys improve energy absorption efficiency by 40%; graphene-coated springs significantly enhance conductivity and fatigue resistance.

3. Lightweight Special Alloys

-

Titanium alloy springs are widely used in aircraft engine valve springs due to their strength-to-weight ratio advantage (40% lower density than steel).

-

Magnesium-based degradable alloys are used for temporary bone nails, eliminating the need for secondary surgery to remove them.

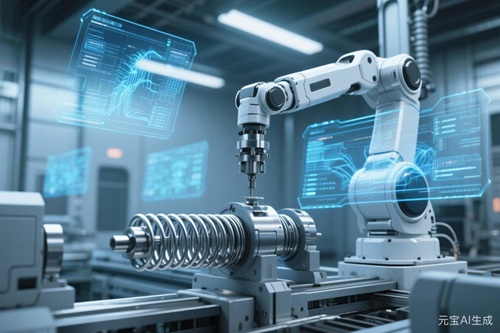

Manufacturing Process Innovation: Intelligence and Precision

Intelligent Spring Manufacturing System

Digital full-process and AI-driven process optimization

4D Printing and Nano Manufacturing

Multi-material collaborative construction of honeycomb biomimetic spring structures

High-Precision Machining Technology

Laser cutting and precision grinding technology

1. Intelligent Spring Manufacturing System

-

Digital full-process: CAD parametric design combined with finite element analysis (FEA) optimizes spring stiffness and fatigue life; digital twin technology maps physical spring states in real time, achieving 95% accuracy in automotive suspension spring fault warnings.

-

AI-driven process optimization: Machine learning analyzes production data to dynamically adjust heat treatment temperatures and winding speeds. One company improved spring fatigue life from 500,000 to 800,000 cycles using AI models.

Frontier Application Scenarios

1. High-End Industry and Aerospace

-

Automotive Field

Adaptive suspension springs dynamically adjust stiffness, improving shock absorption efficiency by 30%; memory alloy springs are used in transmission clutches, optimizing pedal feel with nonlinear force curves.

-

Aerospace Field

Carbon nanotube-SMA composite springs are used in satellite solar panel deployment mechanisms, resisting radiation and withstanding extreme orbital temperature differences.

2. Biomedical Revolution

-

Implant Devices

Nickel-titanium alloy spinal correction rods dynamically adjust support force through two-way memory effects; degradable magnesium alloy springs provide continuous pressure during fracture healing.

-

Targeted Therapy

Nano spring-driven drug capsules precisely release drugs to tumor sites under magnetic field guidance.

Future Trends and Challenges

1. Technical Bottlenecks

-

Multi-field coupling control: Insufficient coordination accuracy between temperature and magnetic fields makes it difficult to ensure phase transition consistency in SMA springs.

-

Miniaturization limits: Online detection accuracy for springs with diameters <0.5mm still needs breakthroughs.

2. Intelligent and Green Development Paths

-

AI deep empowerment: MIT teams use reinforcement learning to optimize 4D printing parameters, achieving real-time calibration of spring deformation.

-

Circular economy: Develop recyclable shape memory polymers (SMPs) to reduce dependence on nickel-titanium alloys; energy consumption monitoring systems reduce carbon emissions in heat treatment processes by 30%.

Previous:Bedstory Sleep Tale - Cloud Roll Ultra-Silent Mattress

Next:no more