Why Choose US?

Contact US

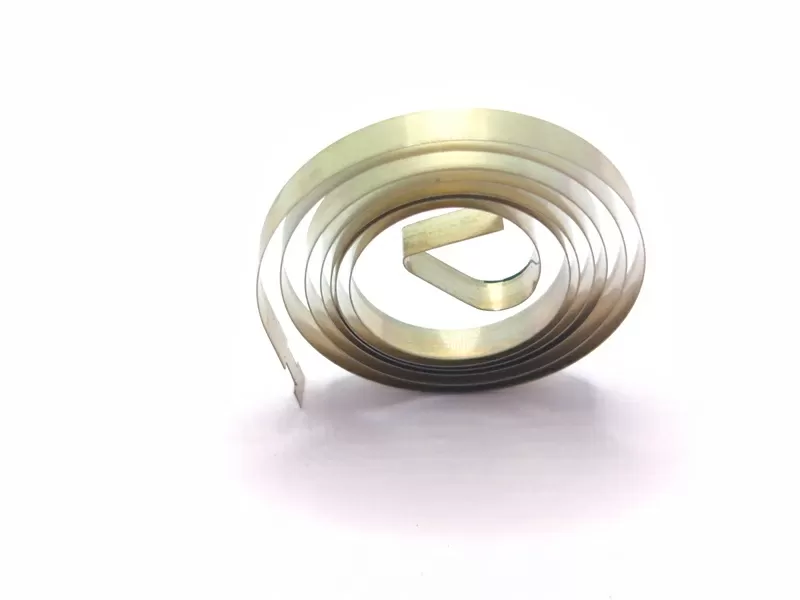

What is Clockwork Spring?

A constant force spring is a specially designed flat spiral spring that delivers near-constant force during extension. With force variation within ±5%, it's widely used in seat belts, medical devices and roller shades.-

Helical,clockwork,Constant For···

Helical,clockwork,Constant Force Spring

-

Helical,clockwork,Constant For···

Helical,clockwork,Constant Force Spring

Read more

-

Spiral,Pipe suspension

Spiral,Pipe suspension

-

Spiral,Pipe suspension

Spiral,Pipe suspension

Read more