-

精密弹簧

>

-

线材成型件

>

-

精密冲压

>

-

精密轴类

>

为什么选择我们?

✔

定制解决方案

根据您的具体负载、空间和环境需求量身定制

✔

ISO 9001 认证

全流程严格质量控制

✔

快速原型制作

5-7天提供测试样品

✔

全球供应链

北美、欧洲及亚洲可靠交付

联系我们

邮箱: sales@lihongsprings.com

手机: +86 176 6501 0974

WhatsApp: +86 150 1844 0213

传真: +86 0769-8532 4238

地址: 广东省东莞市大岭山镇扬朗路446号1栋101室

-

多层平端顶对顶卷绕波形弹簧

多层平端顶对顶卷绕波形弹簧

-

多层平端顶对顶卷绕波形弹簧

多层平端顶对顶卷绕波形弹簧

Read more

-

螺旋式304不锈钢内置式中型发动机···

螺旋式304不锈钢内置式中型发动机油封弹簧

-

螺旋式304不锈钢内置式中型发动机···

螺旋式304不锈钢内置式中型发动机油封弹簧

Read more

-

多层闭端顶对顶卷绕波形弹簧

多层闭端顶对顶卷绕波形弹簧

-

多层闭端顶对顶卷绕波形弹簧

多层闭端顶对顶卷绕波形弹簧

Read more

-

单层闭端冲压波形弹簧

单层闭端冲压波形弹簧

-

单层闭端冲压波形弹簧

单层闭端冲压波形弹簧

Read more

-

螺旋式304不锈钢内置式小型发动机···

螺旋式304不锈钢内置式小型发动机油封弹簧

-

螺旋式304不锈钢内置式小型发动机···

螺旋式304不锈钢内置式小型发动机油封弹簧

Read more

-

螺旋式管道悬挂用不锈钢恒力弹簧

螺旋式管道悬挂用不锈钢恒力弹簧

-

螺旋式管道悬挂用不锈钢恒力弹簧

螺旋式管道悬挂用不锈钢恒力弹簧

Read more

-

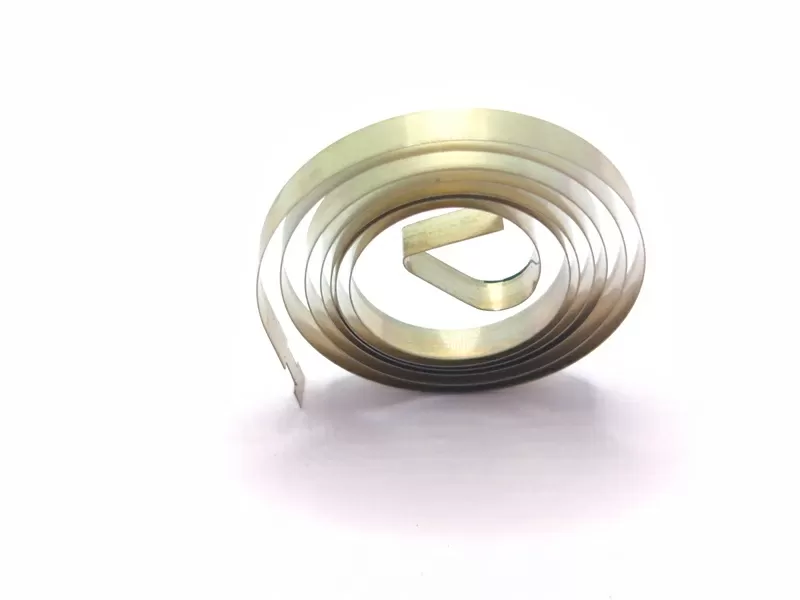

螺旋式钟表机构用不锈钢恒力弹簧

螺旋式钟表机构用不锈钢恒力弹簧

-

螺旋式钟表机构用不锈钢恒力弹簧

螺旋式钟表机构用不锈钢恒力弹簧

Read more